Menu

- Home

- About

- Circuit BreakersWhy Retrofit Switchgear?

A Guide to Replacement Switchgear

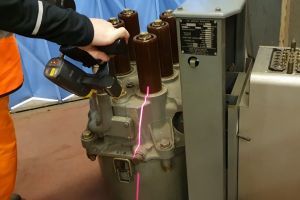

Laser Scanning

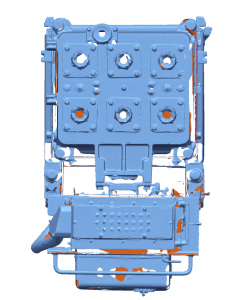

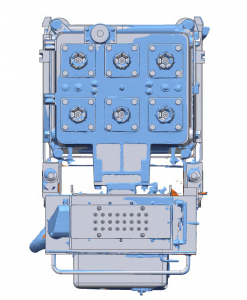

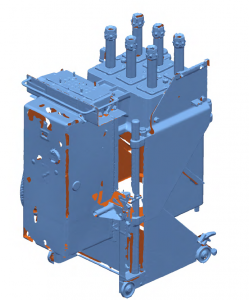

Retrofit Switchgear

Replacement for GEC BVP17, Brush VSI/VMV, SWS C4X, D4X and Reyrolle LMT Oil Breakers with Magnetic Actuator

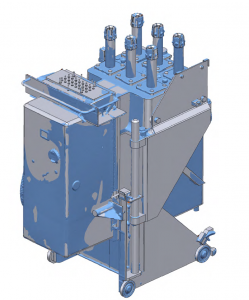

VOR-M Vacuum Circuit Breaker Retrofit

Replacement for GEC BVP17/VMX, SWS, CX, DX and Brush VSI Oil Breakers with Spring Mechanism

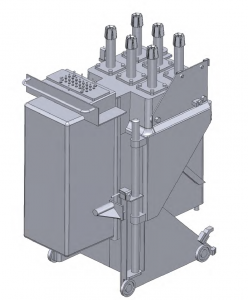

VOR-S Vacuum Circuit Breaker Retrofit

Accessories

Remote RF SwitchingRetrofits for English Electric Air Breakers

E3 Vacuum Circuit Breaker Retrofit

E5, E7 and E8 Vacuum Circuit Breaker Retrofits

Retrofits for Reyrolle Air Breakers and Contactors

S14A Vacuum Contactor Retrofit

S27A Vacuum Circuit Breaker Retrofit

S36A and S45A Vacuum Circuit Breaker Retrofit

Retrofits for Whipp & Bourne Breakers and Contactors

AK Vacuum Contactor Retrofit

AH Vacuum Circuit Breaker Retrofit

- Protection Relays

Motor Protection

Motorvision (MV2)

Motor Protection

MPR3E5 | MPR3000

Motor Protection & Control

MicroMotor | MPC3000 | Vision 3000

Primacon

Motor Arc Protection (MAP)

Transformer and Feeder Protection

Feeder Protection

MR-IE | MR-I | MR-E | MR-REF | MR-VT | MR-CS | MR-NVD

Feeder Protection & Control

MicroFeeder | Feedervision (FV2, EFV2, FVD, EFVD) | Advanced Feedervision (AFV2, AFVD)

Transformer Differential

MR-DIFF | MR-DT2

Automatic Recloser

VISIONrGenerator Protection

Generator Protection

MR-REF3 | MR-FF | MR-VE | MR-IV | MR-NS | MR-MF | MR-RP | MR-SZ | MR-GD | MR-FT

Other Protection Applications

Trip Circuit Supervision

MR-TCS | TCS Lite

Accessories

Low Power Current Sensor

Xcell Data Concentrator

Resistor & Metrosils

Current Transformers

Smart Card

Communication Leads

Vision Control 3 Software

- Industries

- Resources

- Contact Us